How Aldridge Engineering Solves the Industry’s Toughest Challenges

Innovation is deeply embedded in the history of Aldridge. For decades, our teams have looked beyond off-the-shelf equipment to engineer custom solutions for the most complex infrastructure challenges in the country. This napkin to reality culture is not just a modern trend but a long-standing commitment to self-performing work with precision and safety. At Aldridge, we believe that the right tools are just as important as the right team. Our fleet is not just a collection of vehicles but a specialized mobile workshop designed to tackle the industry’s most challenging work. We employ the most passionate problem solvers and give them the resources to turn conceptual ideas into field-ready reality.

Engineering Efficiency

Our history of internal innovation stretches back over twenty years with the development of specialized rail-borne machines and custom work platforms. By adapting equipment to work in unique environments like elevated rail systems or tight urban tunnels, we gained the ability to access sites where standard machinery cannot operate. This same spirit is what led to the creation of the Sully Stick and our specialized Non Entry Rescue trailers. These systems allow for personnel recovery without requiring others to enter a hazardous environment, ensuring we are constantly turning past experiences into future protections. Safety is the primary motivator for many of our custom builds, and these innovations are driven by the people who know the work best.

A Culture of Problem Solvers

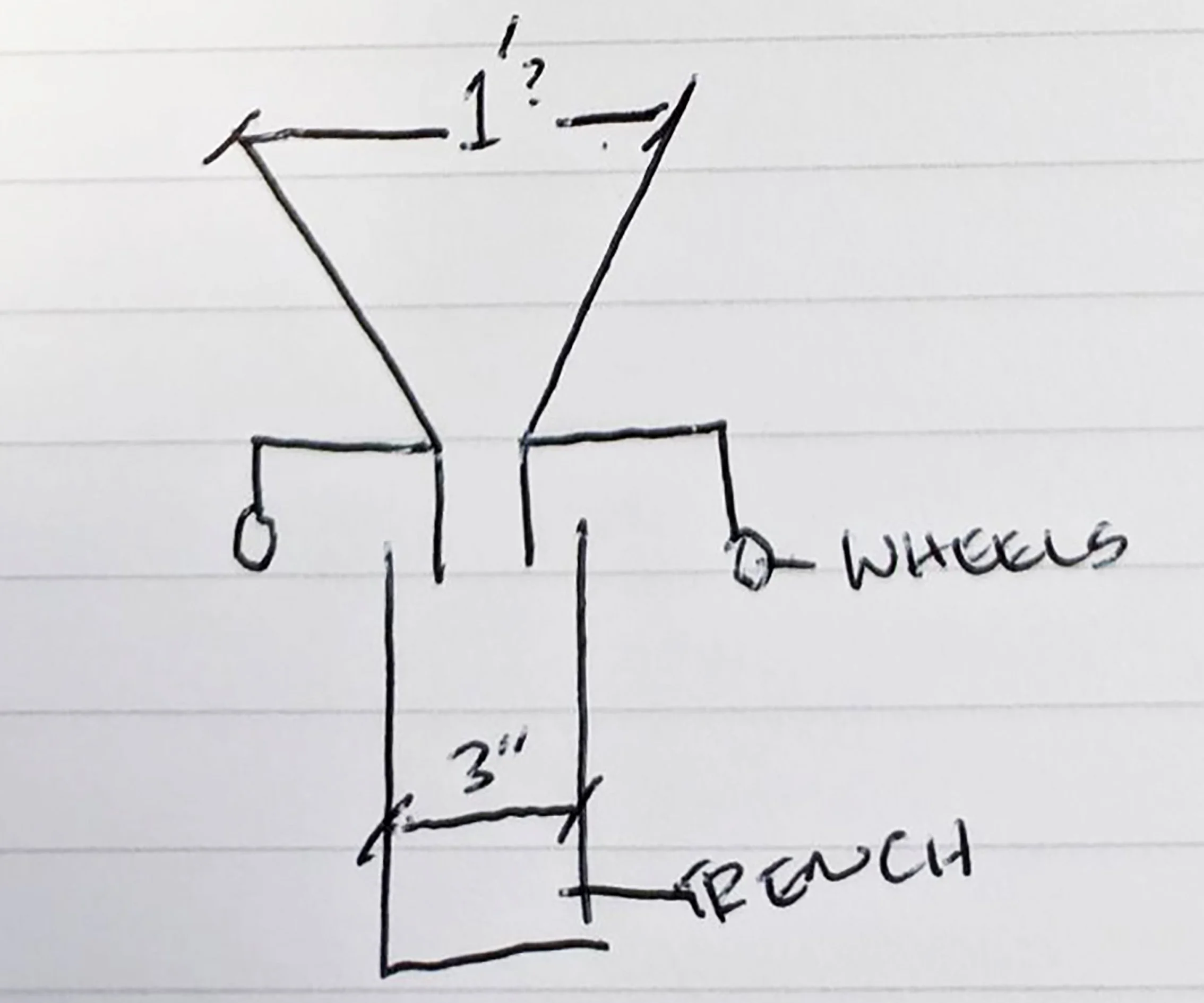

Field-driven ingenuity remains at the heart of our operations. Whether we are working on a small foundation or a massive transit overhaul, our crews are constantly looking for ways to enhance efficiency. When faced with a bottleneck on a job site, they don't wait for a solution to hit the market. They collaborate with our fabrication shop to create tools that can suppress silica dust, automate repetitive tasks, or streamline the installation of hundreds of feet of conduit at a time. By maintaining a fleet of over 2,000 assets and investing in our own shops, we have the freedom to customize our equipment for every project need. Whether we are retrofitting equipment for high-stakes rail upgrades or utilizing 3D virtual design to plan complex builds, our focus remains on de-risking projects for our clients.

Our people are the industry's most passionate problem solvers, and these innovations are a testament to their dedication to building a safer and more efficient future.